Leading the Way in Asphalt Mixing Plant Innovation

Intelligent, Simple Operation, Faster Production

Solutions We Provide

Our specializes in providing customized solutions for road & bridge construction. Our comprehensive range caters to various project

demands, from urban road construction to large-scale highway projects, airport runways to bridge decks, our asphalt mixing plant ensures

the production of superior asphalt mixes tailored to each unique requirement.

ALQ Stationary Batch Type

Productivity: 80t/h-400 t/h

Feature: Adopting forced mixing technology, high mixing efficiency and good uniformity of the mixture.

Application: highways, national roads and other projects that require high-yield and high-quality asphalt mixtures.

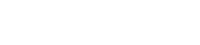

ALYQ Mobile Batch Type

Productivity: 60t/h-160 t/h

Feature: modular design of equipment, quick disassembly and transportation, strong flexibility.

Application: multiple construction sites need to take turns to construct, emergency road repair, temporary road construction, etc.

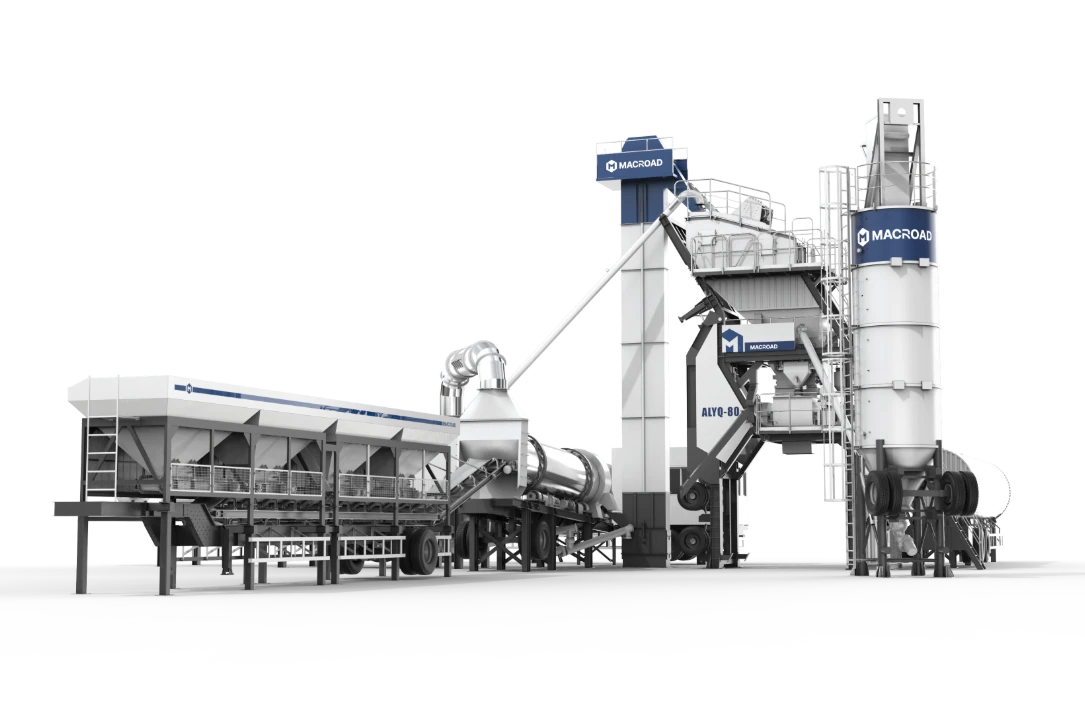

ALT Drum Type

Productivity: 40t/h-160 t/h

Feature: adopting drum mixing technology, simple structure and low maintenance cost.

Application: small and medium-sized road construction: such as urban roads, county and township roads, etc.

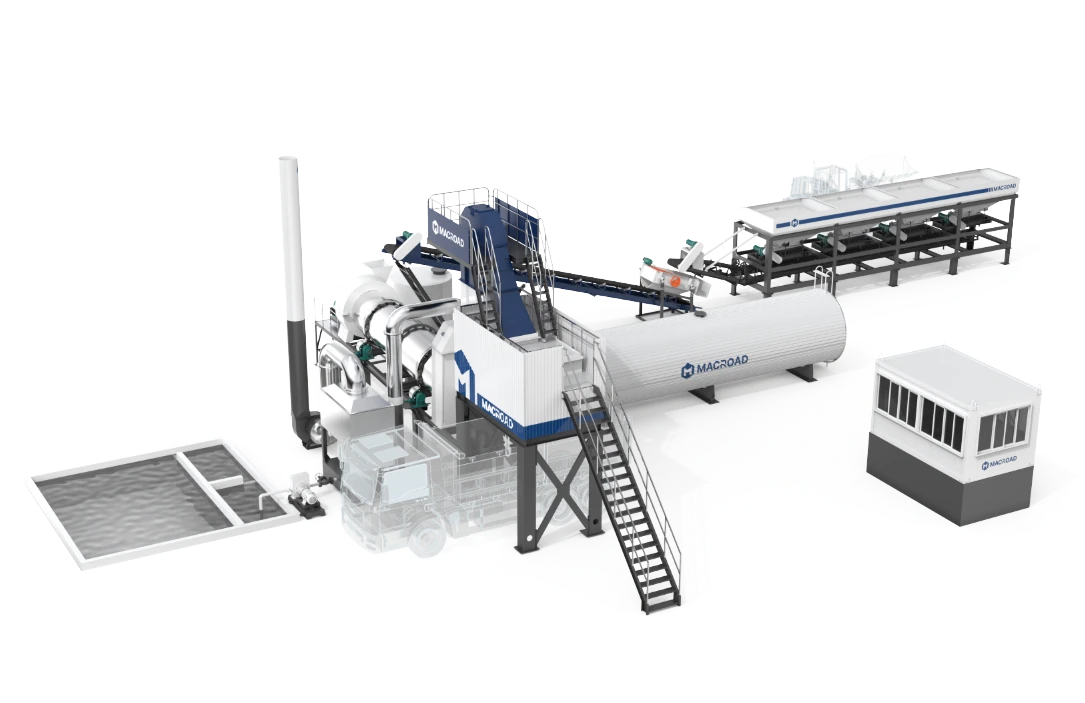

ALYT Mobile Drum Type

Productivity | 40t/h-160 t/h

Feature: easy to transport, suitable for small and medium-sized decentralized projects.

Application: rural road construction, small municipal projects, short-term road repair, temporary parking lot construction, etc.

Project Solutions

Asphalt mixing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been

exported to various countries, for example: the Philippines, Malaysia, Indonesia, Australia, Saudi Arabia, Paraguay, Peru, Chile, Tanzania,

Democratic Republic of the Congo, Fiji, Papua New Guinea, Guyana, Jamaica, etc;

About Macroad

Our Service

Customized Design Plans

If you are new to the asphalt mixing plant, or need customized plans for your project, we can help you to find the most suitable plan for you. we are aimed to provide solution with reasonable price and perfect service.

Factory Inspecting Test

Before transportation we will has strict machine inspection to ensure product quality, such as, material supervision, welding inspection, coating inspection, packing inspection, loading inspection, etc.

Spare Parts Exchange & Maintenance Service

Providing 12 months warranty. After that we also provide regular maintenance service to you. We will provide you necessary parts and training operator how to exchange them. If we have overseas branches nearby, we will sent our resident engineer to have regular revisit.

Installation & Commissioning Service

As soon as the machine was shipped to destination, our after-sales engineer will fly to local work-site to help installation, running test and operation training service.

Specialist for Road & Bridge Construction

We Export Road & Bridge Construction Equipment Worldwide, Please feel free to contact us.

Contact Us