Integrated intelligent control system: one-button start and stop;

IOT remote monitoring system: real-time monitoring of equipment operation status

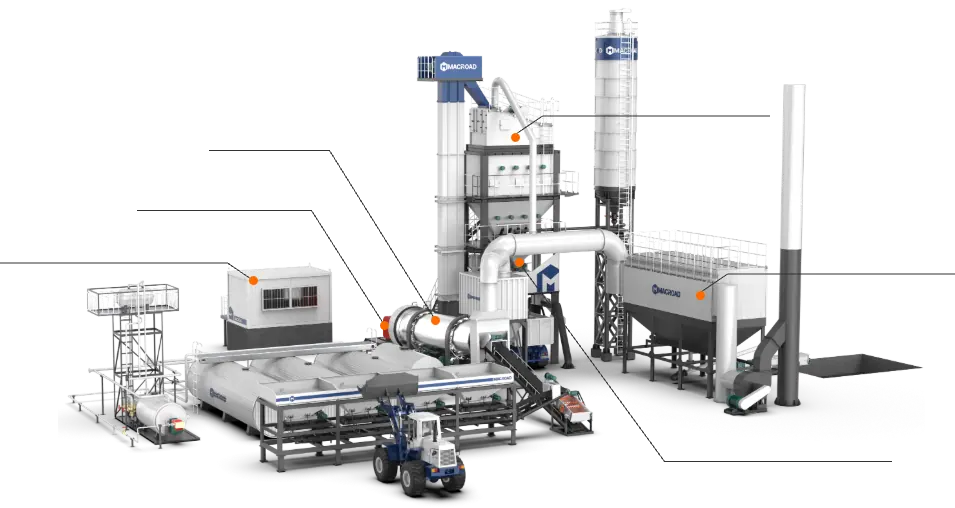

Types of Our Asphalt Plants

Stationary Batch Type

Hot Models:80t/h120t/h160t/h200t/h

Productivity: 80t/h-400 t/h

Application: highway mainline construction, airport runway engineering, large-scale infrastructure in urban core areas and other high-precision grading and ultra-large capacity demand projects;

Get A Quote

Mobile Batch Type

Hot Models:80t/h100t/h120t/h

Productivity: 80t/h-120 t/h

Application: Provincial/national highway construction, and expansion, urban road construction and other multi-section transfers and medium capacity demand;

Get A Quote

Stationary Drum Type

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-120 t/h

Application: urban road construction, port logistics channel road paving and other long-term stable production projects;

Get A Quote

Mobile Drum Type

Hot Models:40t/h60t/h80t/h120t/h

Productivity: 40t/h-120 t/h

Application: urban roads, rural roads and other scattered sections and short-term demand projects;

Get A Quote

Applications of Asphalt Paving

The application of macroad asphalt mixing plant currently covers road construction, maintenance, recycling. With the advancement of technology, its application scope is also developing towards environmental protection (recycled asphalt), intelligence (warm mix technology) and multi-functionality (permeable/colored asphalt). Different scenarios require adjustment of asphalt ratio, additives and production processes to meet the balance between performance and cost. At present, the application areas we cover are:

Road construction

Asphalt stations are mainly used to produce asphalt mixtures required for road construction, including highways, municipal roads, rural roads, etc.

Pavement maintenance and repair

Special engineering applications

Urban infrastructure construction

Our Different Solutions to Customer Concerns

We are always a trusted partner in the industry! We have been deeply involved in the field of asphalt mixtures for many years and have provided precise and adaptive solutions for hundreds of road projects around the world; currently including highways, municipal trunk roads, airport runways, port yards and other special scenarios.

Customer Concerns: Looking for economic efficiency;

Solution: The ALT80 asphalt mixing plant for rural roads can save you 20% of costs;

Customer concerns: Need quick repairs?

Solution: ALYT ALYT120 mobile drum type, 24-hour cold patch material supply, so that the road can be “repaired and opened immediately”;

Upgrades of the Main Components

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Drying drum

Burner system

Control system

Vibrating screen

Dust filter

Mixing unit

Drying drum

- Efficient aggregate drying with precise temperature control

- Double-layer insulated discharge pipe ensures 100% temperature compliance

Burner system

- Provides stable heat and optimized fuel efficiency for the drying and heating process.

- Heating system is optional:coal, diesel, natural gas.

Vibrating screen

- Enhanced screening accuracy;

- 30% larger area + quick-release screen structure

Mixing unit

- 4/5-bin cold hoppers (20% larger single-bin capacity)

- Separate storage & weighing system (aggregate ±1%, powder/additive ±0.5%) Ensures uniform mixing for durable asphalt mixtures

Dust filter

- Two-stage dust removal (Cyclone + Bag filter), upgraded recycling

- Cyclone collects reusable sand; Bag filter ensures thorough purification

Control system

- Triple control modes (touch screen/PC/buttons)

- Automated operation guarantees precision & productivity

Our Service

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Customized Design Plans

If you are new to the asphalt mixing plant, or need customized plans for your project, we can help you to find the most suitable plan for you. we are aimed to provide solution with reasonable price and perfect service.

Factory Inspecting Test

Before transportation we will has strict machine inspection to ensure product quality, such as, material supervision, welding inspection, coating inspection, packing inspection, loading inspection, etc.

Spare Parts Exchange & Maintenance Service

Providing 12 months warranty. After that we also provide regular maintenance service to you. We will provide you necessary parts and training operator how to exchange them. If we have overseas branches nearby, we will sent our resident engineer to have regular revisit.

Installation & Commissioning Service

As soon as the machine was shipped to destination, our after-sales engineer will fly to local work-site to help installation, running test and operation training service.

Related Products for Road Construction

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include: