Global Top 500 Cooperative Supplier

One-button Start and Stop, Automatic Operation

Mobile asphalt mixing plant is asphalt mix manufacturing equipment in the form of one or some mobile modules mounted on chassis, so it features fast relocation and rapid reassembly, and pre-production preparation time can be saved greatly. If you want to buy a mobile asphalt plant with flexible operation modes and high production efficiency? Macroad asphalt plant is an excellent choice!

Applications of the Mobile Asphalt Mixing Plant

Mobile Asphalt plant suitable for small and medium-sized road construction project required frequent relocation. For example, decentralized road projects, municipal maintenance projects, special scenario projects and strategic support projects, etc.

Road Construction

Asphalt stations are mainly used to produce asphalt mixtures required for road construction, including highways, municipal roads, rural roads, etc.

Pavement Maintenance and Repair

Special Engineering Applications

Urban Infrastructure Construction

Types of Mobile Asphalt Plants

Macroad has designed and manufactured 2 types and more than 100 sets of mobile asphalt mixing plants for global customers, including mobile batch asphalt plant, mobile drum asphalt plant and portable mobile asphalt plant with the capacity from 10t/h to 160t/h. They all have the characteristics of modular structure, easy transportation and installation, and quick relocation. Customers can choose the suitable type based on their requirements and preferences.

ALYQ Asphalt Mixing Plant (Mobile Batch Type)

Model: ALYQ60~ALYQ160

Capacity: 60 t/h ~ 160 t/h

Highlights: Batch mix, precise screening, accurate weighing, high quality output; easy for installation, fast relocation.

ALYT Asphalt Mixing Plant (Mobile Drum Type)

Model: ALYT40~ALYT160

Capacity: 40 t/h ~ 160 t/h

Highlights: Continuous production, drum mix; modular structure, ease of relocation, lower initial investment.

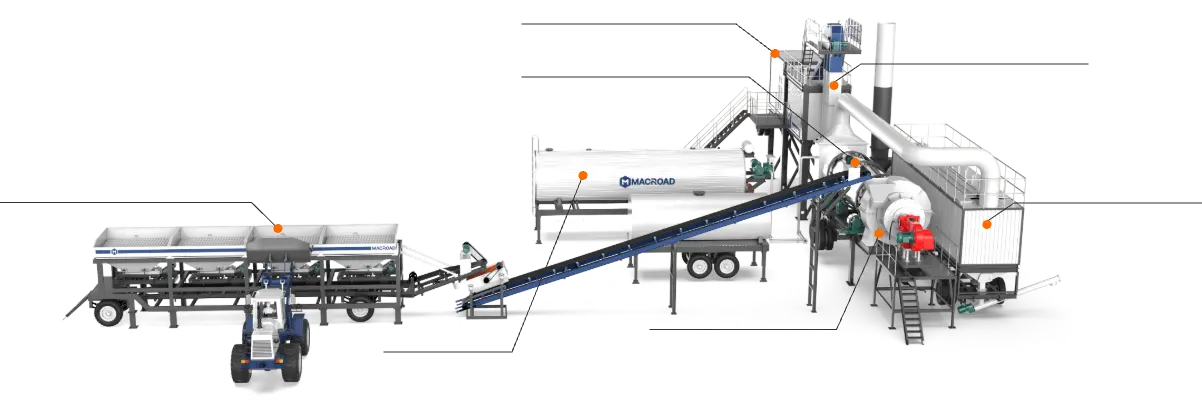

Components of Mobile Asphalt Plants

Mobile Asphalt plants are precisely coordinated by multiple core systems to ensure efficient and stable asphalt production. From aggregate transportation to drying and heating, from mixing to dust removal, each link is crucial. In order to give you a more intuitive understanding of the equipment structure, we will show you the cold aggregate supply system, drying and heating system, lifting system, mixing system, dust removal system, powder supply system, asphalt supply system, gas system and control system to help you gain a deeper understanding of the efficient operation of the MACROAD asphalt plant.

Cold Aggregate Feeding System

bitumen Tank

Control System

Mixing System

Drying & Heating System

Bucket Elevator

Dust Removal System

Aggregate Batching System

- Main includes: batch hopper, feeding belt, collecting belt, vibrating screen and belt conveyor.

- The hopper capacity is upgraded to 9m³*4, and the belt conveyor is equipped with a pull-rope switch emergency stop device.

Drying & Mixing System

- Consists of drying cylinders, combustion devices, and oil ignition system components, etc.

- Various fuel options (oil, fine coal, natural gas) to save operating costs.

Dust Collecting System

- Two collecting levels, cyclone dust filter and bag dust filter.

- Compared with gravity dust removal, cyclone dust removal has better dust removal effect, reduces the load of bag dust collector, and prolongs its life.

Bitumen Supply System

- Composed of bitumen tank, bitumen gear pump, pipes, and bitumen spray tube.

- The default fuel for the burner of the thermal oil furnace is diesel, with options for coal and natural gas.

Electrical Control System

- Adopts centralized control technology, composed of distribution cabinets, control room, and other small auxiliaries.

- Four operation modes: control cabinet button/touch screen, computer, and mobile phone app.

Mobile Chassis

- Mobile chassis and substructure can be added to the main components of the asphalt plant.

- Easy to disassemble and assemble, making the asphalt plant portable and easy to relocate.

Global Cases

Asphalt mixing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been exported to various countries, for example: Malaysia, Indonesia, Saudi Arabia, Paraguay, Peru, Kazakhstan, Uzbekistan, Democratic Republic of the Congo, Fiji, Papua New Guinea, Guyana, Jamaica, etc.

ALYT100 Mobile Asphalt Drum Mix Plant in Ecuador

Project detail: The project site is a small island, and the cost of purchasing and transporting asphalt is high.

Solution: Flexibility of ALYT100 Mobile Asphalt Plant is customers value most. Easy transportation and quick setup. Self-produced asphalt, easy to use, and cost-saving.

ALYT80 Asphalt Mixing Plant Successfully Operated in Papua New Guinea

Project detail: The customer needed an efficient and easy-to-install asphalt plant to accelerate road construction while minimizing energy consumption.

Solution: The ALYT80 Mobile Asphalt Mixing Plant offered continuous production, a modular design for quick installation, and low energy consumption with environmental benefits. This ensured stable operation and on-time, high-quality delivery.

Our Service

The performance of an asphalt mixing plant hinges on the seamless integration of its core components, each playing a vital role in ensuring productivity and high-quality output. Key components include:

Customized Design Plans

If you are new to the asphalt mixing plant, or need customized plans for your project, we can help you to find the most suitable plan for you. we are aimed to provide solution with reasonable price and perfect service.

Factory Inspecting Test

Before transportation we will has strict machine inspection to ensure product quality, such as, material supervision, welding inspection, coating inspection, packing inspection, loading inspection, etc.

Spare Parts Exchange & Maintenance Service

Providing 12 months warranty. After that we also provide regular maintenance service to you. We will provide you necessary parts and training operator how to exchange them. If we have overseas branches nearby, we will sent our resident engineer to have regular revisit.

Installation & Commissioning Service

As soon as the machine was shipped to destination, our after-sales engineer will fly to local work-site to help installation, running test and operation training service.

Related Products for Road Construction

As a trusted supplier of asphalt plants, we also provide a complete range of road building equipment to meet all your project needs. Whether you focus on asphalt production, paving, or subgrade stabilization, we offer the support to keep your operations running smoothly.

Modified Bitumen Plant

Asphalt Paver

Stabilized Soil Mixing Plant